Innergie – Achieve sustainability with every effort, has utilized PCR (Post Consumer Recycled) plastic in our products’ casings. But what exactly is PCR plastic, and why is its use a significant step towards energy conservation and carbon reduction?

What is PCR?

PCR stands for Post Consumer Recycled, meaning the plastic comes from plastic that has been recycled after consumer use. For example, water bottles, beverage cups, food containers, electronic product components, etc. Recycled plastic is mixed with virgin plastic based on the product’s requirements, such as color and safety, to create new plastic products – of course, the quality of the PCR plastic needs to be assured and certified.

Moving Towards a New Cycle

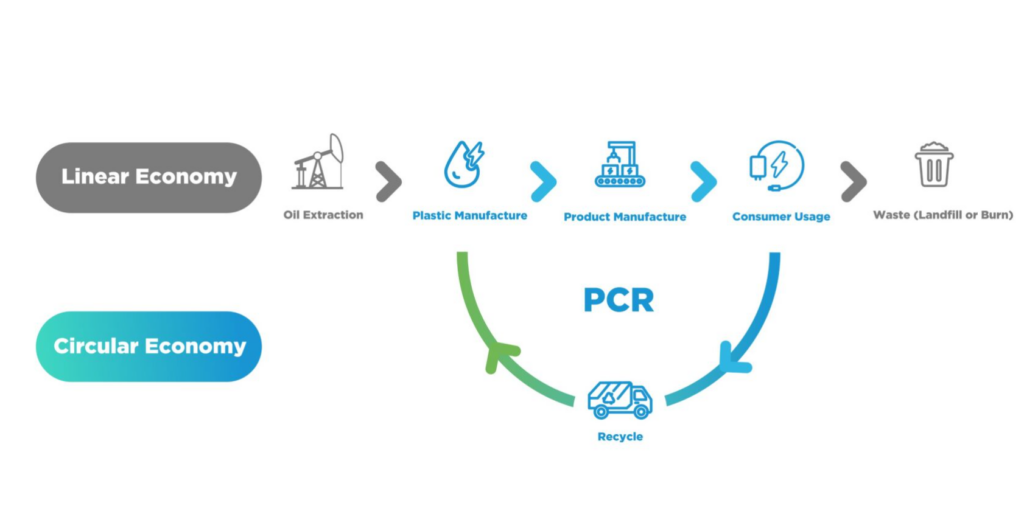

Traditionally, plastic manufacturing and waste disposal followed a linear economic model, involving processes from petroleum extraction, refining, manufacturing, processing, consumption, disposal, to incineration or land filling. Approximately 90% of the carbon footprint generated throughout the entire lifecycle comes from petroleum manufacturing and conversion processes. PCR plastic aims to create a closed-loop system for plastic reuse. Through various recycling techniques, recycled materials are re-manufactured, reintegrated into the plastic manufacturing chain, reducing the need for petroleum extraction and usage. This, in turn, helps achieve carbon reduction goals.

Since the invention of plastic from petrochemical materials in the 1900s, global plastic usage has increased year by year. Despite global efforts to reduce plastic use in recent decades, the actual rate of growth still far surpasses the rate of reduction. Widespread application of PCR plastic can effectively reduce carbon emissions and energy consumption.

Your Choice = Positive Effect to the Earth

Recent studies indicate that recycling 1 ton of plastic waste is equivalent to saving over 2 tons of petroleum resources, reducing energy consumption from extraction, and minimizing landfill space. With current known recycling technologies, 1 ton of discarded plastic can yield approximately 800 kilograms of recycled plastic at its highest efficiency. In reality, not every recycling facility achieves an 80% plastic recycling rate, and the recycling rate is closely tied to the quality of the recycled plastic. However, if consumers consciously choose products made from PCR materials, it can stimulate businesses to increase demand for discarded plastic, significantly accelerating plastic recycling and reducing plastic incineration. This gradual shift can alter the entire operation and recycling mode of the plastic product industry, ultimately reducing the extraction of disposable natural resources, decreasing landfilling and incineration, and lowering energy consumption and greenhouse gas emissions.

In line with our brand mission-“Greener. Smarter. Together.”, Innergie, a brand of Delta Electronics, has roll out material change in our One For All USB-C fast charger. The plastic casing of these products uses 75-95%% PCR material. Compared to traditional plastic materials, the carbon dioxide emissions can be reduced by approximately 65-85%. Combined with Innergie’s consistent high quality, high conversion efficiency, and low standby power consumption, this further emphasizes our commitment to environmental protection.

By choosing products made from PCR plastic, you can contribute to the perfection of the circular economy. Take action and cast your vote for a more sustainable planet. However, the most fundamental approach is to reuse and reduce impulsive consumption. We can start by examining our needs and selecting durable, quality-assured products.

Find Your PCR Product: