The market is flooded with a wide array of charger styles. Have you ever wondered why some chargers are starting at just ten dollars, while others fetch prices in the hundred? The old adage “you get what you pay for” rings true here, and unfortunately, some manufacturers prioritize profits over quality, resorting to cost-cutting measures. The price of a charger should indeed reflect its quality, and four key factors significantly influence its price: Production and Quality Control, Materials, Product Design, and Protection Mechanisms.

1. Production and Quality Control

- Automated Production: Leveraging electronic arm production reduces human errors and elevates product quality.

- Process Management: Implementing an efficient source-to-process management mechanism enhances part matching between manufacturers, ensuring consistent specifications for each product batch and reducing the occurrence of defects.

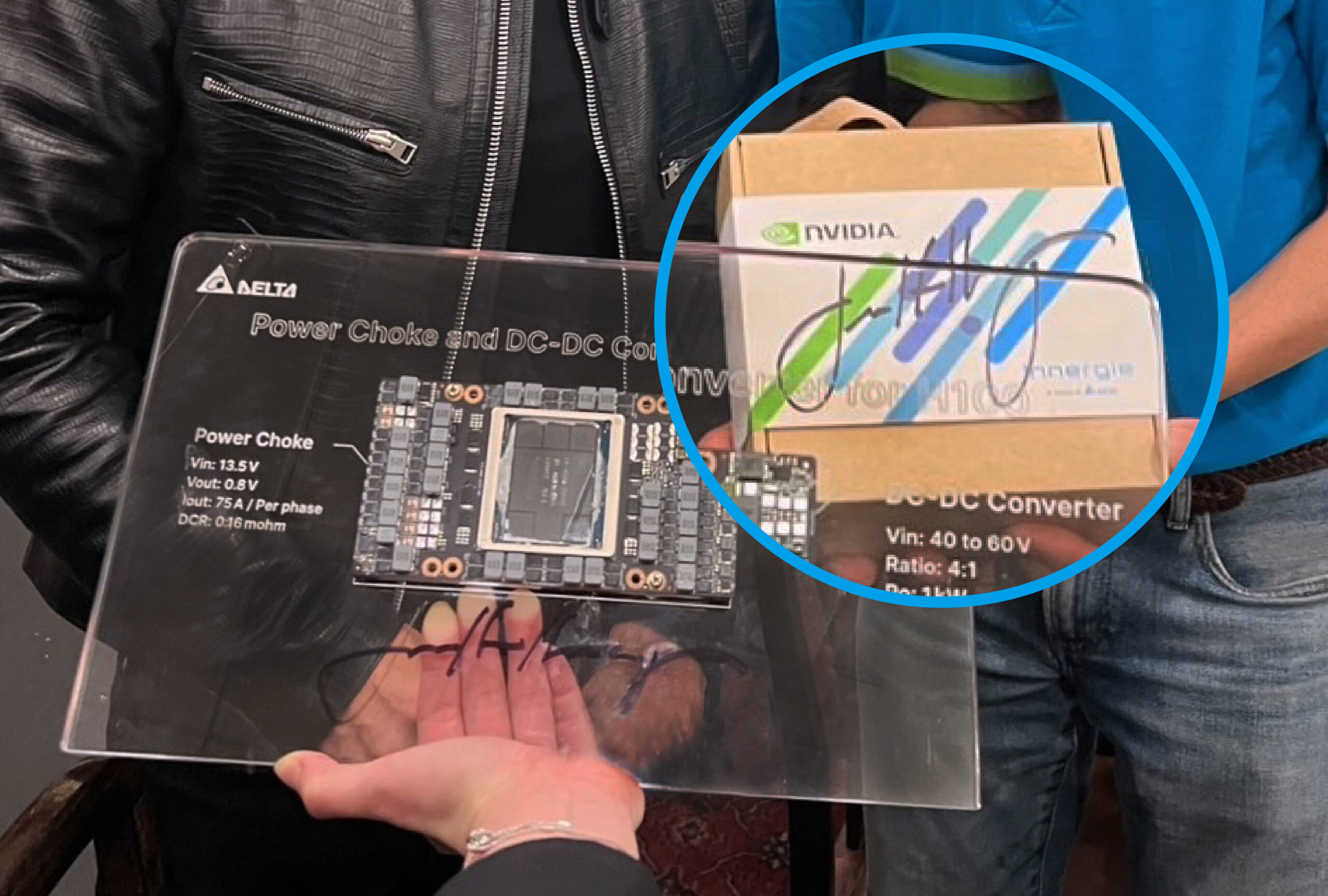

Surprisingly, a seemingly small charger consists of over 300 parts, and any mistakes during production or with part quality can lead to an unstable power supply. All Innergie products manufactured on Delta’s production line boast a high degree of automation in the assembly process, ensuring a high yield rate of quality products entering the market.

2. Material

- Electronic Components: Older version charging components tend to be less efficient, and using small or early specification components from lesser-known brands can hamper charging performance.

- Component Materials: Subpar materials may result in unstable DC voltage, affecting the charger’s touch screen and potentially causing screen disruptions.

- Metal Materials: The right metal materials, such as those used in the plug, can resist current and enhance conductivity efficiency.

- Case Material: The case material affects resistance to drops, flame resistance, and other aspects that ensure the charger can withstand daily collisions and wear.

Innergie products use parts from Delta Electronics’ audited manufacturers, which ensures longevity and durable quality for stable and extended performance.

Moreover, good product design and robust protection mechanisms are crucial for user safety:

3. Product Design

- Circuit Design: An overly simplistic circuit design may lead to short circuits when insufficient safety space exists between the circuit and parts.

- Protection Design: Ensuring adequate protective coatings, adhesive fixings, and isolations are in place to enhance safety.

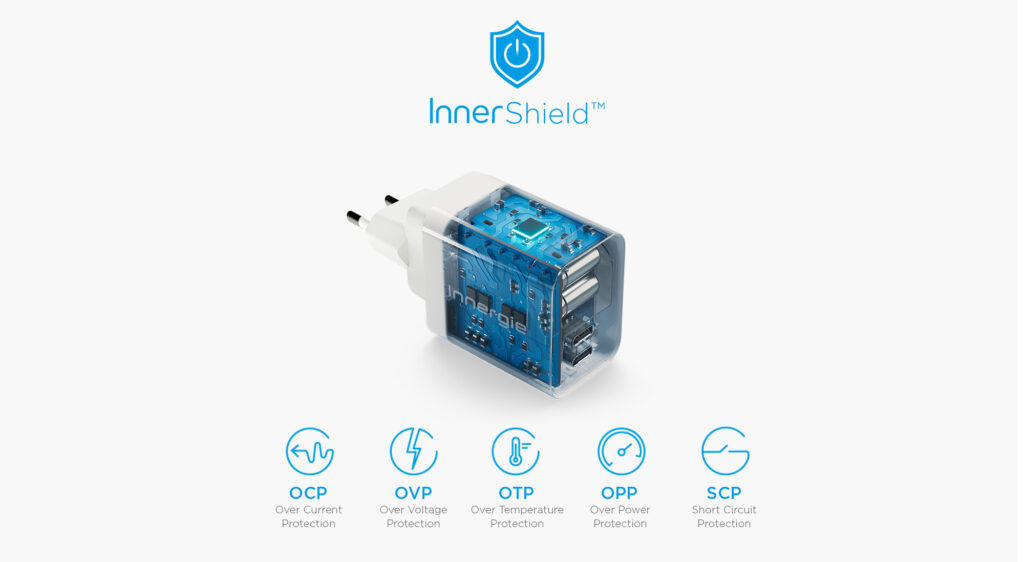

4. Protection Mechanisms

The presence of a protection mechanism significantly impacts the charger’s price. Some low-priced chargers may lack such mechanisms, posing potential safety hazards. In contrast, high-quality chargers feature multiple protection mechanisms.

Innergie’s full range of chargers not only complies with national safety regulations but also surpasses more stringent standards with 600 hours of Delta internal testing. It incorporates the unique InnerShield™ five safety mechanisms, including over-voltage protection, over-current protection, and overheating protection, ensuring the safety of both the charging device and the user.

In conclusion, the market’s charger price disparities primarily stem from the materials used and the presence of protection mechanisms. For long-term usage, it is advisable not to compromise safety and quality for the sake of saving a little money. Opt for internationally certified brands with impeccable protection mechanisms to ensure safe and efficient charging.

Innergie chargers originate from Delta Electronics’ over 50 years of professional power supply manufacturing expertise, and all products come with a 3-year warranty and multinational safety certificates, guaranteeing both your charging devices and electrical safety.

Innergie holds certification from numerous international safety standards, and all Innergie products are crafted from durable PC material.